Manufacturing

- Select

Home | Services & Solutions | Drug Product | Parenteral | Manufacturing

The state-of-the-art parenteral drug product manufacturing facilities are in Wuxi City drug product site in China and will be expanded to our Couvet site in Switzerland and Middletown Delaware site in the US.

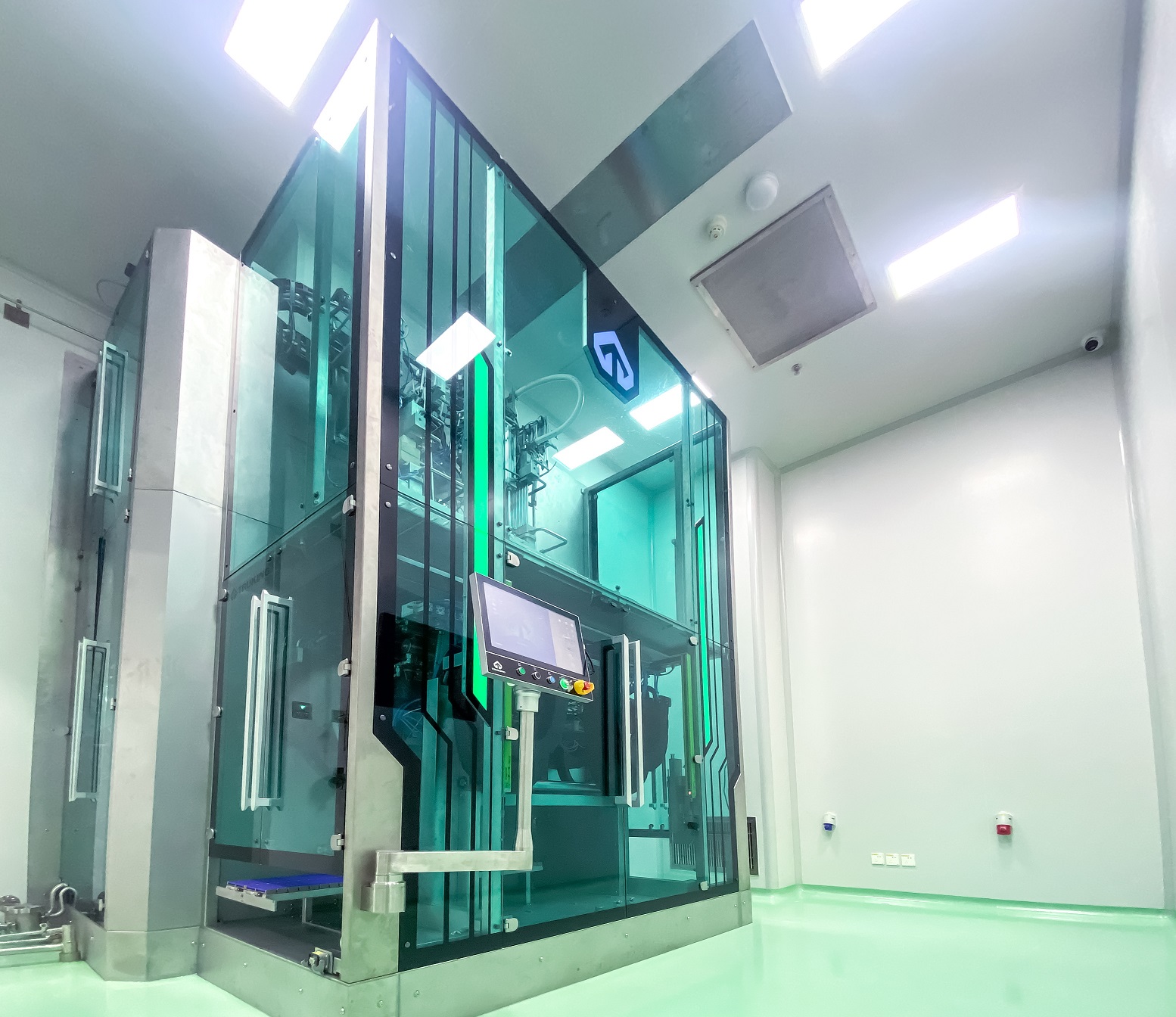

We support various dosage forms and filling formats at any scale from preclinical to commercial manufacturing. We have 5 production lines are featuring fully enclosed isolation systems and automated filling lines, and we support high potency injectable drug product.

Currently, our production capacity is 70 million doses per year.

Drug Types

- Small molecule

- Oligonucleotide

- Peptide

- Synthetic conjugate

- mRNA/DNA (LNP)

Dose Forms

- Solution

- Emulsion / Suspension

- Lyophilized powder

- In-situ-forming hydrogels

- Advanced formulation (e.g., Liposomes, Lipid Nanoparticles, Nano Particles)

Filling Formats

- Vials

- Prefilled syringes

- Cartridges

- LDPE ampoules

Sterilization

- Sterile filtration

- Heat-moist sterilization

- Irradiation

Manufacturing Platform

Our sterile plants have passed multiple inspections from global regulatory agencies and clients every year.

- Filling speed: up to 200 units/min

- Batch size: 0.5 L – 2,000 L

- Filling volume as low as 2 mL

- Lyophilizers: up to 20 m2

- < 1% line loss in production, saving costly API

- 5 production lines, total capacity 70 million doses per year

- Fully contained, modular design & robotic operation to minimize both microbial contamination and cross-contamination risks

High Potency Injectable Drug

The high potency sterile injectable manufacturing line is located at the drug product site in Wuxi City, China. Its Occupational Exposure Limit (OEL) is 10 ng/m3. The fully enclosed isolation systems and automated filling machines minimize both microbial contamination and cross-contamination risks. The line has two 20m2 lyophilizers and supports liquid and lyophilized vials of various specifications. This line can efficiently perform the filling of up to 200 units per minute, achieving an annual capacity of over 12 million units.

Lipid Nanoparticle GMP Manufacturing

This modular designed LNP manufacturing plant in Wuxi City integrates multi-channel chip, micro-mixer system, and complex preparation system into a multi-channel micro-mixer core LNP manufacturing platform, offering significant advantages in drug-loading, liposome particle size control, and encapsulation efficiency. In addition, the modular design provides greater processing flexibility, enabling this platform to serve a wide range of manufacturing scales from 10-50 L per batch. Read More.

Blow-Fill-Seal Aseptic Filling Line

We have one Blow-Fill-Seal (BFS) aseptic filling line at our drug product site in Wuxi City.

Designed for eye drops and inhalants, this BFS line handles volumes ranging from 0.1 – 10 mL, fills up to 200 units per minute, and has an annual capacity of 9 million units.

Packaging & Labeling

At WuXi STA, we have dedicated outer packaging line for injectable dosage. It supports labeling, automatic box opening and packaging, vial & cartridge automatic cartooning, automatic pallet, drug electronic supervision code and 100% online weighing check under low temperature.

We can provide open study and double-blind labeling options with various formats such as single panel, two panels, booklet, transparent and customized label based on clinical protocol interpretation.

Our packaging teams adheres to strict quality control measures as per compliance.

Please refer to our Clinical Supply Service webpage for storage and distribution service.